Our Advantages-

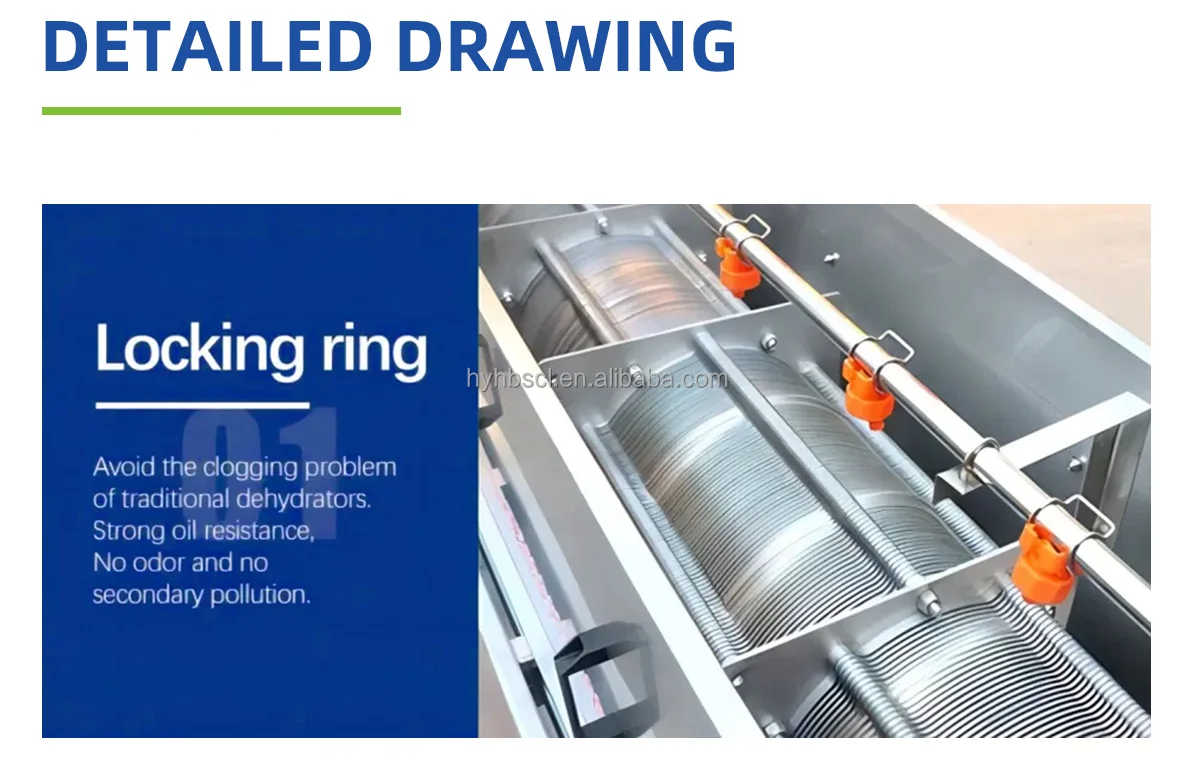

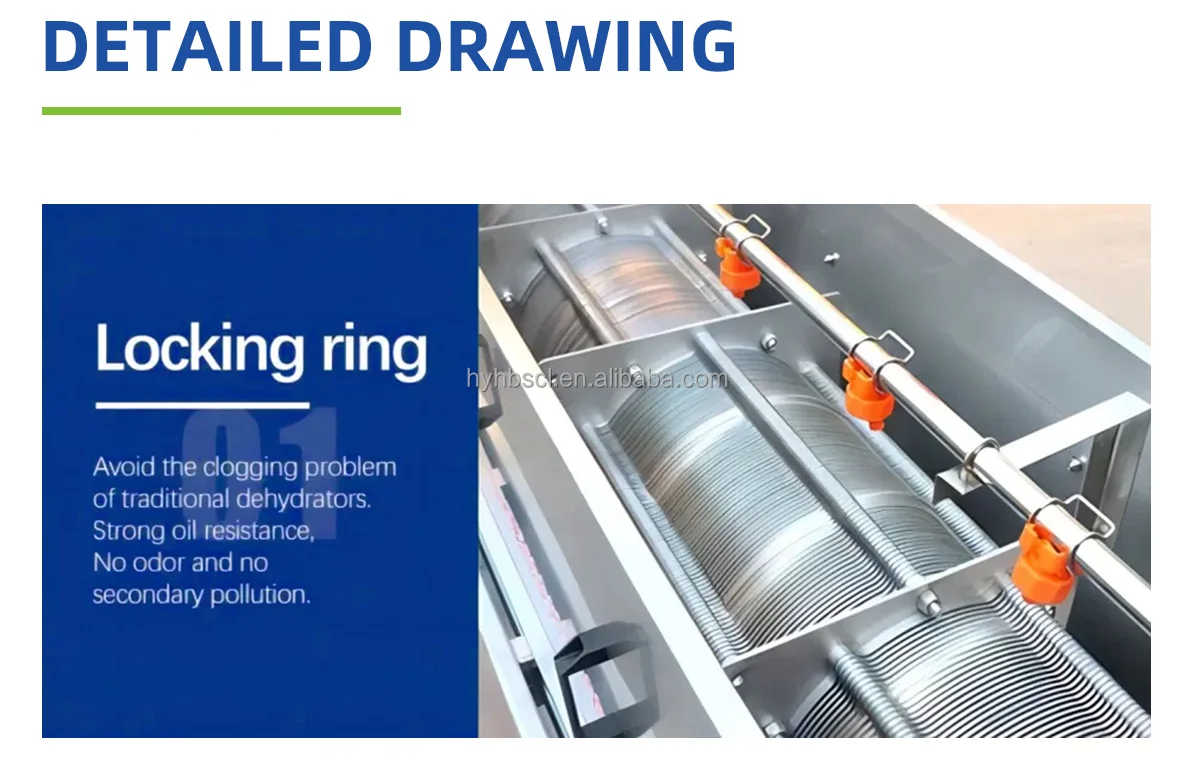

1. Strong ability to resist oily sludge, easy to separate, no cloggingThe dewatering body of the screw stacked sludge dewatering machine is formed in afilter cylinder structure formed by overlapping a fixed ring and a moving ring, and thescrew shaft runs through it. While conveying the sludge, the stacked rotary shaftpushes the swimming ring to make a circular motion, which has the function of auto-matically cleaning the filter seam. Especially for oily sludge with strong viscosity, ithas indisputable advantages compared with traditional dewatering machines. Thedehydration part of the dehydrator is blocked during operation, which will hinder thedischarge of the filtrate, and the dehydration performance will be greatly reduced.

2. Sludge concentration and dehydration are integrated, and low-concentrationsludge can be directly dehydratedAutomatic Spiral Stacked Screw Type Press Sludge Dewatering Machine for Munici-pal Engineering.

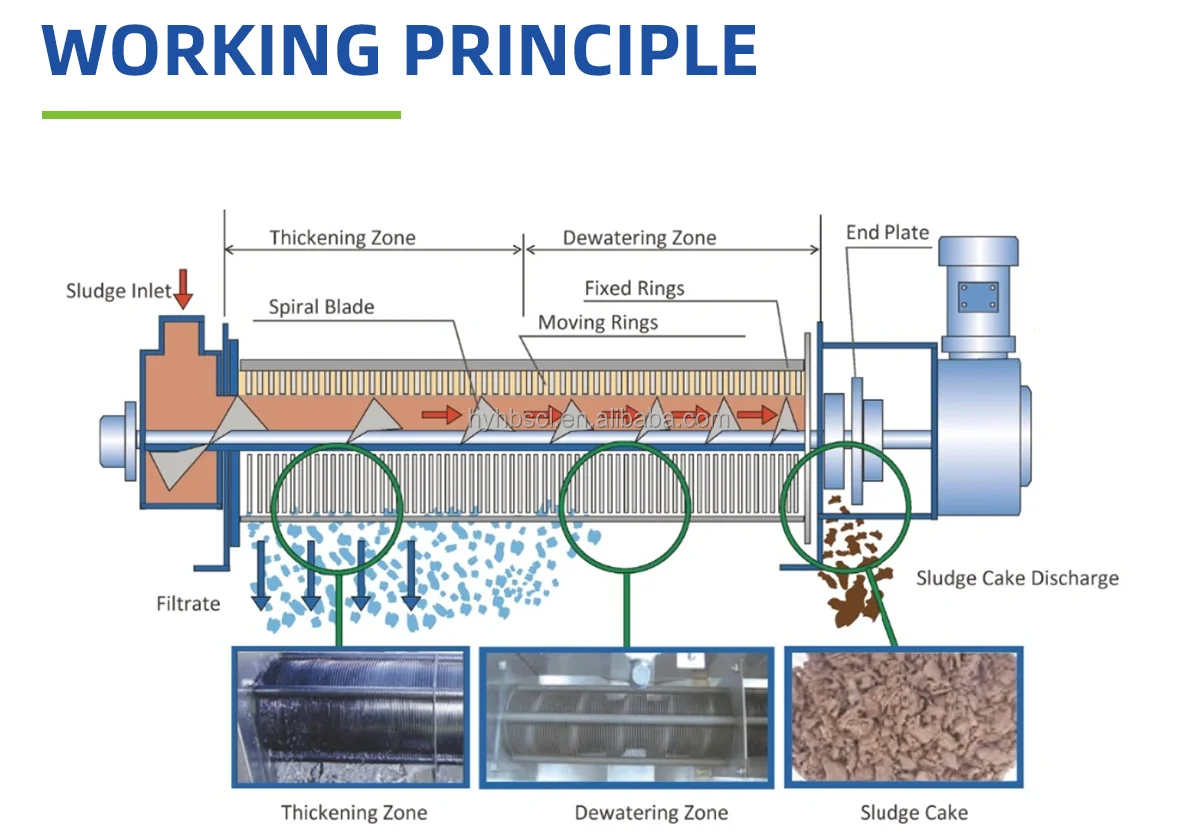

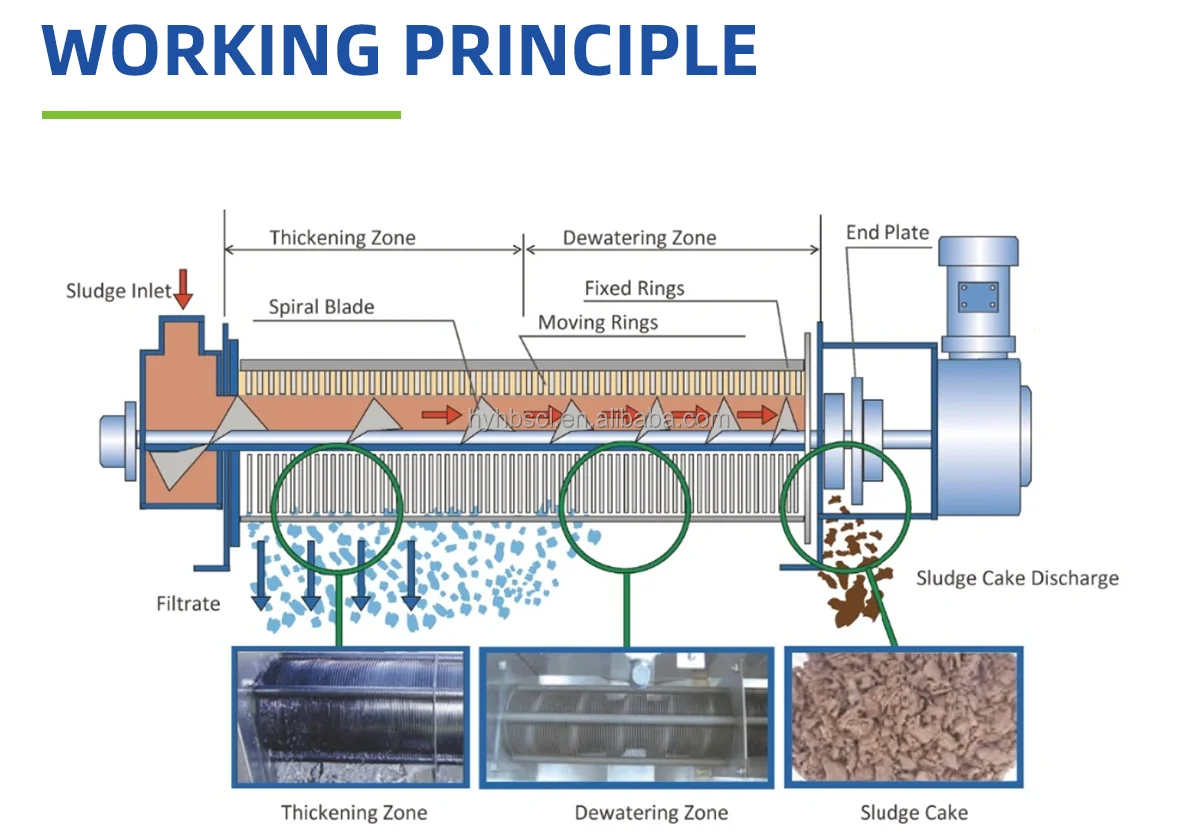

Working Principle:

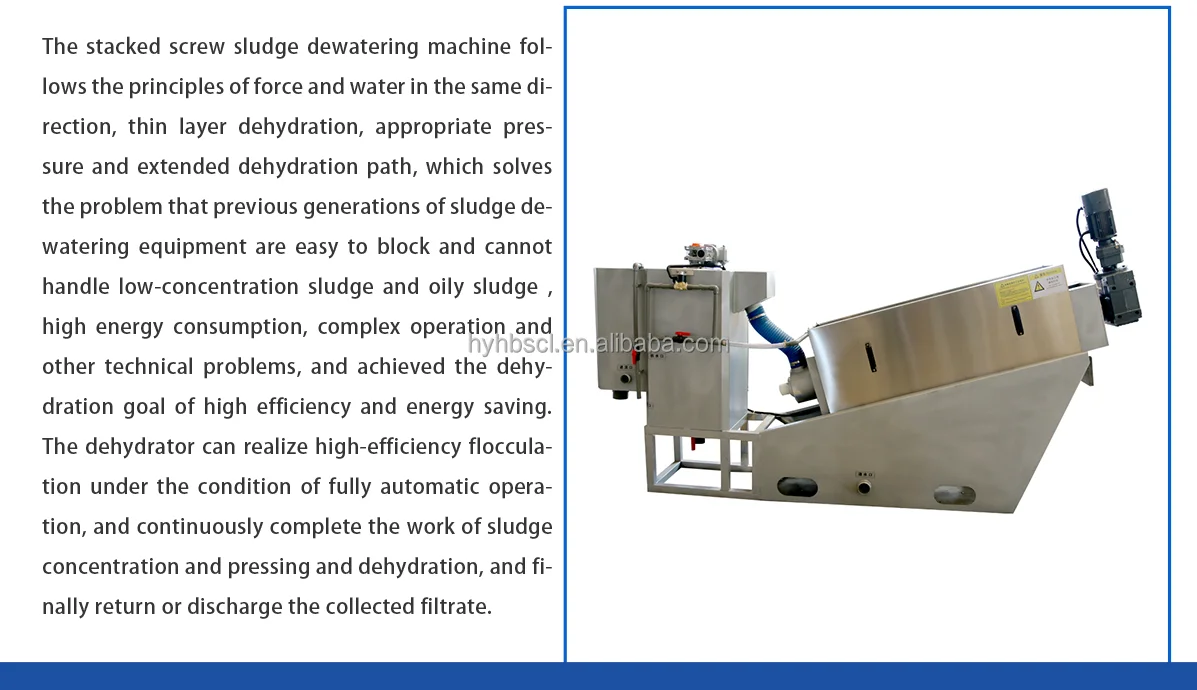

Concentration: When the spiral propeller shaft rotates, the multiple solid and active stacks located at the periphery of the propeller shaft move relative to each other, and the water is filtered out from the gap of the relative moving stacks under the action of gravity, realizing rapid concentration. Under the effect of gravity, water is filtered out from the gap of the relatively moving stacks, realizing rapid concentration. Dewatering: the thickened sludge moves forward with the rotation of the spiral shaft; along the direction of the mud cake outlet, the pitch of the spiral shaft gradually becomes smaller, and the gap between the ring and the ring gradually becomes smaller, and the volume of the spiral cavity shrinks continuously; under the action of the back pressure plate at the outlet, the internal pressure gradually strengthens, and under the continuous operation of the spiral propelling shaft in order to propel it, the water in the sludge is squeezed and discharged, and the solids content of the filter cake is constantly rising, and the continuous dewatering of sludge is realized at last. Self-cleaning: the rotation of the spiral shaft pushes the swimming ring to rotate continuously, and the equipment relies on the movement between the fixed ring and the swimming ring to realize the continuous self-cleaning process, thus cleverly avoiding the clogging problem commonly found in traditional dewatering machines. Thus, it skillfully avoids the clogging problem commonly found in traditional dewatering machines.

| Stacking screw machine | Standard Material | Absolute dry sludge treatment capacity(kg-Ds/h) | Overall dimensionsL*W*H(mm) | Equipment weight(kg) | Power(kw) |

| S.S.304 (optional with other materials) | (L)long | (W)wide | (H)high | Net weight | Working |

| HY101 | 4~10kg-/h | 2200 | 800 | 1300 | 178 | 245 | 1.12 |

| HY201 | 9~20kg-/h | 2900 | 800 | 1500 | 250 | 390 | 1.3 |

| HY202 | 18~40kg-/h | 3000 | 1100 | 1500 | 450 | 650 | 2.05 |

| HY301 | 30~60kg-/h | 3300 | 900 | 1720 | 700 | 1230 | 1.65 |

| HY302 | 60~120kg-/h | 3500 | 1200 | 1720 | 1300 | 2050 | 2.2 |

| HY303 | 90~180kg-/h | 3500 | 1600 | 1700 | 1750 | 3100 | 4.4 |

| HY401 | 80~200kg-/h | 4300 | 1100 | 1900 | 1350 | 3500 | 2.2 |

| HY402 | 160~380kg-/h | 4300 | 1400 | 1900 | 2350 | 3650 | 3.3 |

| HY403 | 240~550kg-/h | 4300 | 2000 | 1950 | 3050 | 4550 | 4.4 |

| HY501 | 200~300kg-/h | 5000 | 1200 | 1900 | 1510 | 3000 | 2.6 |

| HY502 | 400~600kg-/h | 5100 | 1600 | 1900 | 2800 | 4500 | 4.1 |

| HY503 | 600~900kg-/h | 5100 | 2300 | 1900 | 4100 | 5500 | 5.6 |

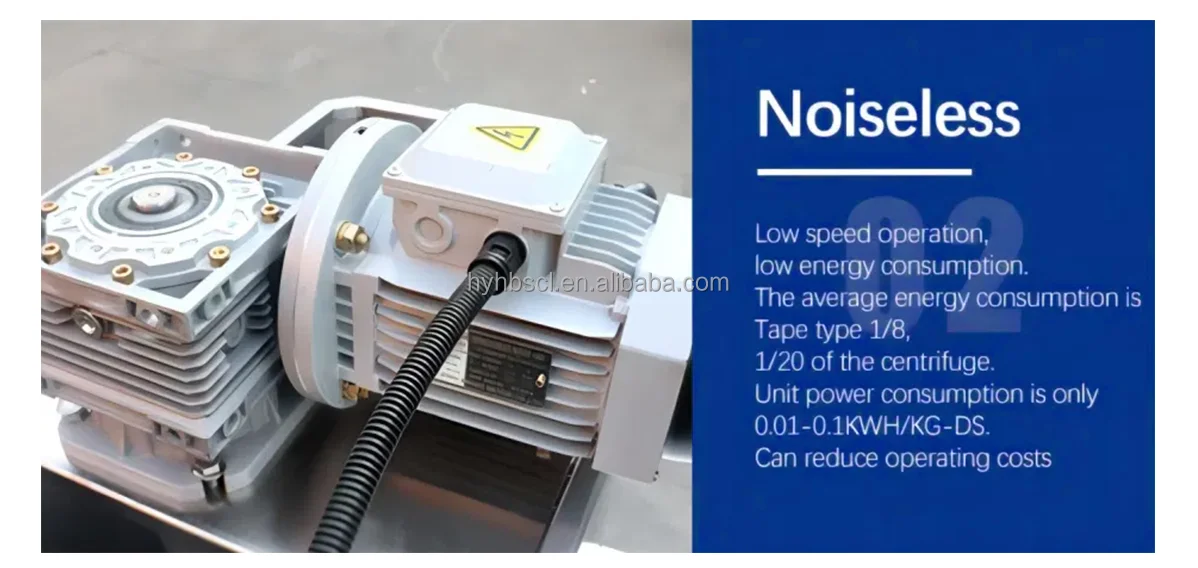

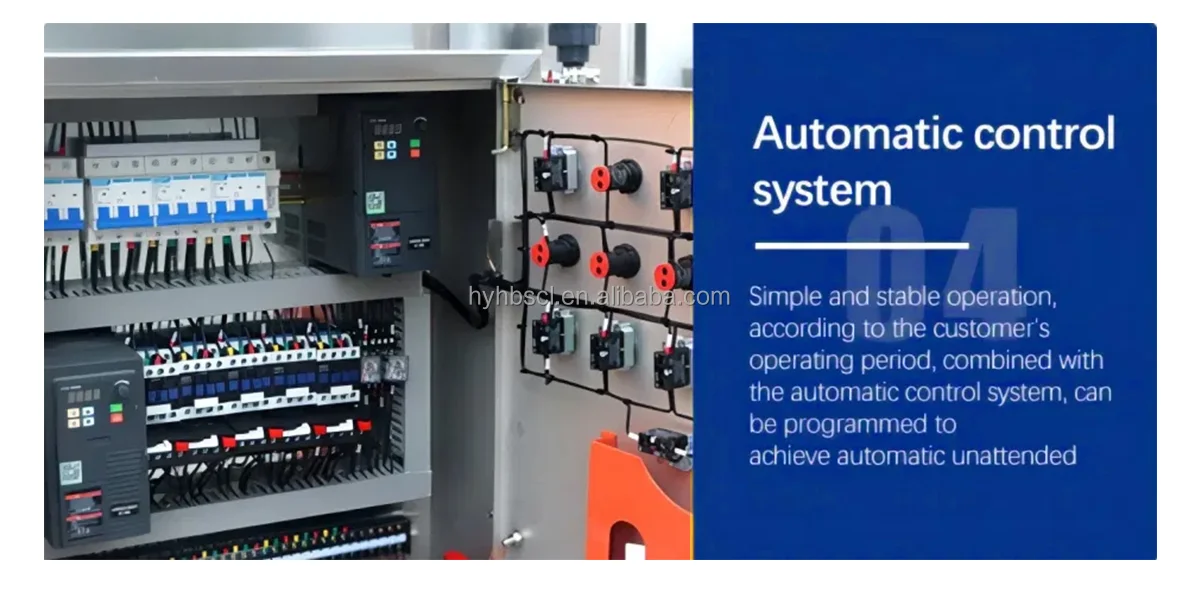

Principles of construction-

The main body of the dewatering machine consists of a stack of fixed andmoving rings, with a screw shaft running through it to form a filtering device.The front section is the thickening section and the rear section is the dewateringsection. The filter slit formed between the fixed and moving rings and the pitchof the screw shaft are gradually reduced from the concentrating section to thedewatering section. The rotation of the screw shaft drives the sludge from thethickening section to the dewatering section, and at the same time, it also drivesthe travelling ring to clean the filtering slit to prevent clogging. it is composed ofdevice, discharging device, air control system, electric control system and so on.