Product Overview

This high-efficiency sewage treatment plant integrates lamella clarifier technology with biological treatment, achieving rapid solid-liquid separation and deep pollutant removal . The lamella clarifier—composed of inclined parallel plates (60° angle)—increases the sedimentation area by 5-8 times compared to traditional horizontal clarifiers, reducing the plant’s footprint by 60% . The system handles sewage volumes from 50m³/d to 5000m³/d, with effluent meeting national Grade A discharge standards (GB 18918-2002) . It is suitable for large residential communities, industrial parks, and urban fringe areas lacking centralized sewage infrastructure, featuring automatic operation and low maintenance costs .

Product Features

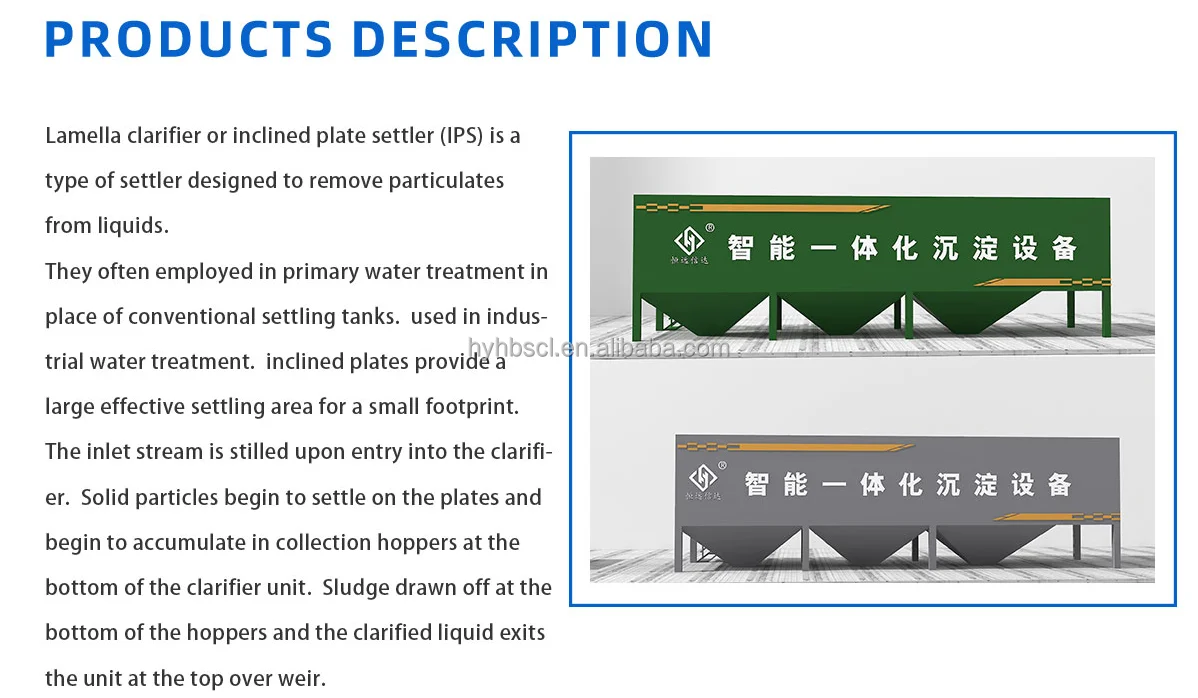

Efficient Solid-Liquid Separation

The lamella clarifier’s inclined plates shorten the sedimentation distance of suspended solids (SS), enabling SS removal rates of over 98% . It also incorporates a sludge scraper system that automatically collects settled sludge, reducing manual cleaning frequency .

Enhanced Biological Treatment

Combines anoxic-oxic (A/O) biological reaction with the lamella clarifier: the A/O module decomposes organic matter (BOD removal rate ≥95%) and denitrifies nitrogen (ammonia nitrogen removal rate ≥90%), while the clarifier ensures clear effluent . The biological tank uses porous polyurethane filler, which increases microbial attachment area by 30% compared to conventional fillers .

Weather Adaptability

The plant’s enclosed structure with thermal insulation maintains stable operation in extreme temperatures (-20°C to 50°C) . In cold regions, an internal heating system keeps the biological tank temperature above 10°C, preventing microbial activity decline .

Smart Monitoring

Equipped with online sensors for pH, COD, SS, and turbidity, which transmit real-time data to the PLC control system . The system automatically adjusts aeration volume and sludge discharge frequency based on water quality changes, ensuring consistent treatment efficiency .

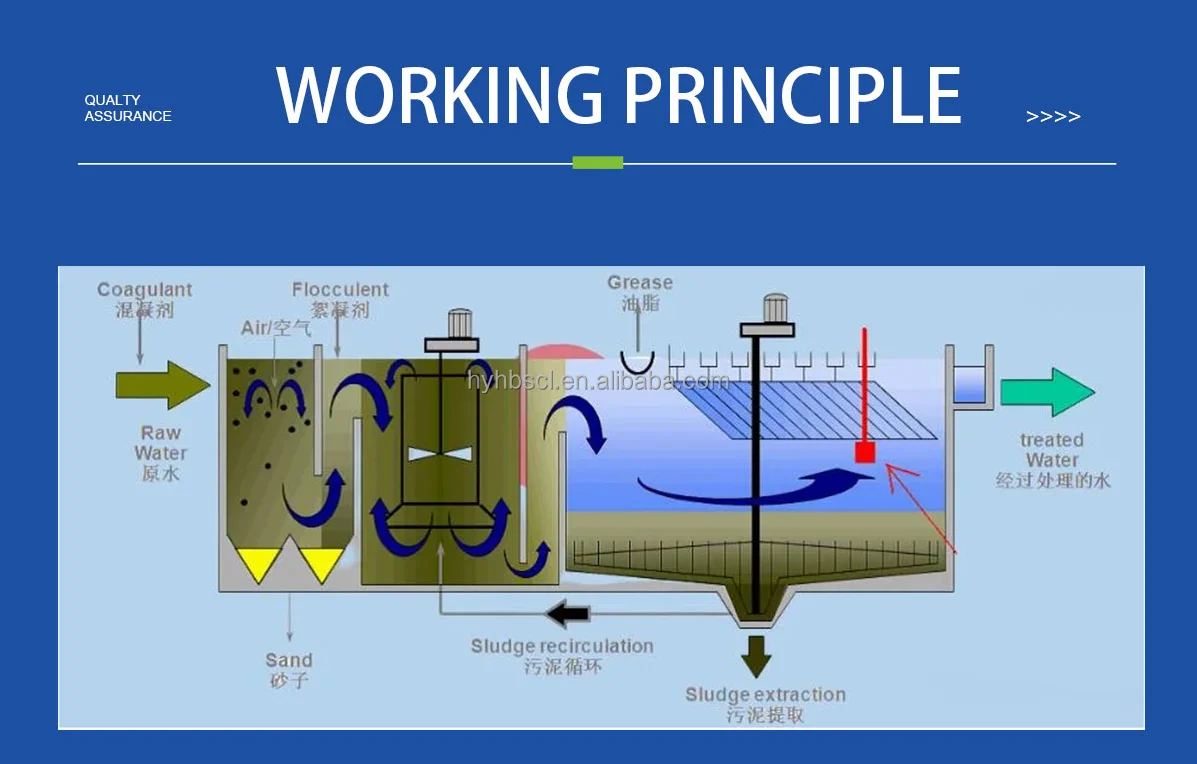

Applications

Large Residential Communities

Serves communities with 5,000-50,000 residents, treating domestic sewage and reusing part of the effluent for landscape irrigation and road cleaning—saving 30% of tap water consumption for the community .

Industrial Parks (Light & Heavy Industry)

Treats mixed wastewater from machinery manufacturing, electronics, and chemical industries. For example, it reduces SS in machinery cleaning wastewater from 800mg/L to ≤10mg/L, meeting industrial discharge requirements .

Urban Sewage Pumping Stations

Acts as a pre-treatment unit for large urban sewage systems, reducing the load on central treatment plants by separating suspended solids and partially decomposing organic matter .

FAQ

How often does the lamella clarifier need cleaning?

The automatic sludge scraper operates daily, and the plates require chemical cleaning (using 5% hydrochloric acid) every 6 months to remove scale. The system alerts operators when cleaning is needed via the control panel .

Can it handle shock loads (sudden increase in sewage volume)?

Yes, the plant has a 20% buffer capacity. When sewage volume exceeds the design capacity by up to 20%, the lamella clarifier’s high sedimentation efficiency and the biological tank’s microbial reserve maintain stable effluent quality .

What is the sludge disposal method?

The collected sludge has a moisture content of 95%, which can be dewatered to 60% using a plate-and-frame filter press (optional accessory). The dewatered sludge is suitable for landfill or composting .

Is the plant noisy during operation?

The main noise sources are aeration blowers, which are installed in sound-insulated enclosures. The noise level at the plant boundary is ≤55dB, complying with residential area noise standards .