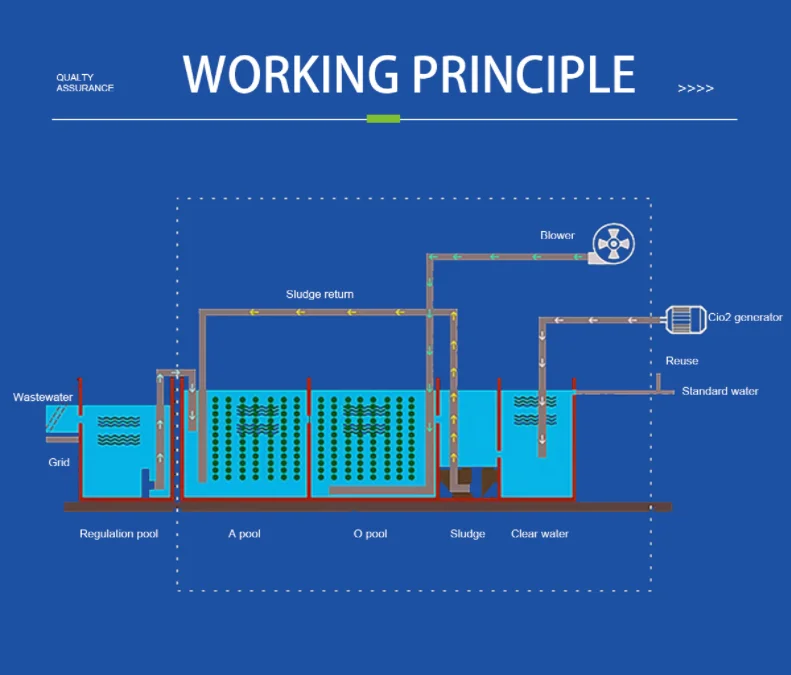

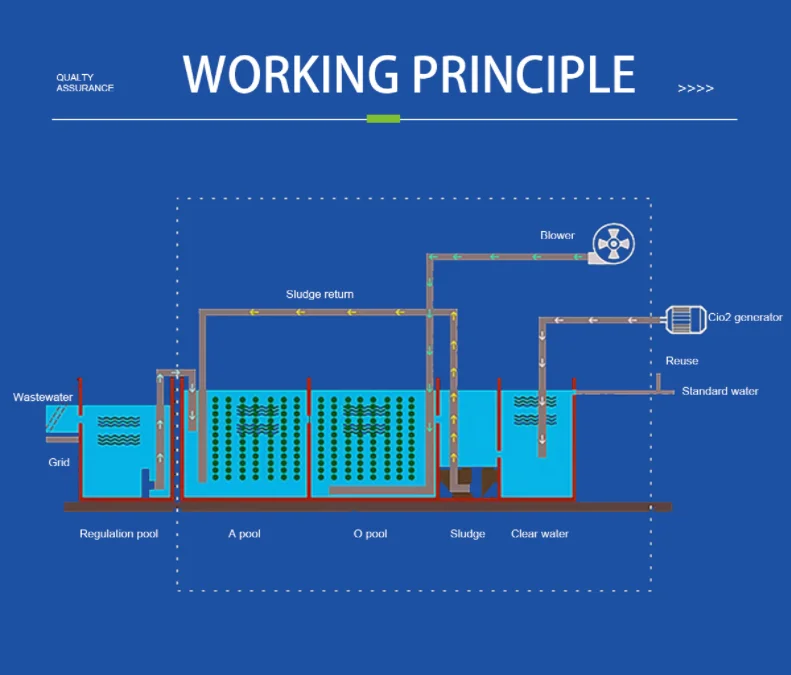

Product Overview

This wastewater treatment plant compact sewage filter treatment equipment is designed for small-scale, low-concentration sewage treatment, integrating physical filtration and biological purification in a space-saving structure . Unlike large plants, it features a multi-layer filter system (sand, activated carbon, ceramic membrane) and a miniaturized biological filter, reducing overall volume to 1.5m³-5m³—suitable for small offices, restaurants, and family communities . The system handles sewage volumes from 1m³/d to 10m³/d, with effluent turbidity ≤5NTU and BOD5 ≤20mg/L, meeting local discharge standards for small-scale sewage . Its plug-and-play design allows easy installation by non-professionals, lowering entry barriers for small users .

Product Features

Multi-Layer Filtration System

The filter unit consists of three layers: a top sand layer (removes large suspended solids), a middle activated carbon layer (absorbs odors and organic matter), and a bottom ceramic membrane layer (filters fine particles and microorganisms) . The ceramic membrane has a pore size of 0.1μm, achieving a SS removal rate of ≥99% .

Efficient Biological Purification

The biological filter uses volcanic rock filler with high porosity (60%), providing a large surface area for microbial attachment. It decomposes organic matter in sewage (BOD5 removal rate ≥90%) and converts ammonia nitrogen to nitrate (removal rate ≥85%) .

Compact & User-Friendly

The equipment has a vertical structure (height 1.8m-2.5m, diameter 0.8m-1.2m), fitting in small spaces like backyards or basements. The control panel features simple buttons (start/stop, backwash, drain) and indicator lights, with no complex parameter settings .

Low Maintenance

The filter system automatically backwashes every 24 hours (using treated water), eliminating manual cleaning. The volcanic rock filler only needs replacement every 3-5 years, and the ceramic membrane has a service life of 2-3 years .

Applications

Small Commercial Establishments

Used in cafes, small restaurants, and beauty salons to treat sewage from dishwashing, laundry, and bathroom use. It reduces the pollutant load before discharging to the municipal sewer, avoiding sewer surcharges .

Family Communities & Gated Villas

Serves small residential groups (5-20 households) that are not connected to the municipal sewage network. The treated water can be used for garden irrigation or car washing .

Laboratory & Small Factories

Treats low-toxicity wastewater from chemical laboratories, electronic component workshops, and small food processing plants (e.g., bakeries), ensuring compliance with local environmental regulations .

Product Details

Water treatment capacity(m3/d) |

External dimensions: length*width*height(mm) |

Equipment weight(t) |

Operating power (kw) |

| 5 |

2500x1000x 1500 |

0.97 |

2.72 |

| 10 |

2500x 1500x 2000 |

1.65 |

2.72 |

| 20 |

5000x1500x 2000 |

2.5 |

3.1 |

| 30 |

5000x2000x 2000 |

2.9 |

3.85 |

| 40 |

6500x 2000x2000 |

4. 36 |

3.85 |

| 50 |

6500x 2000x2500 |

5.07 |

3.85 |

| 60 |

7500x2000x2500 |

5.58 |

4.55 |

| 70 |

7000x 2500x 2500 |

6.31 |

4.55 |

| 80 |

8000x 2500x2500 |

6.88 |

5.35 |

| 100 |

10000x 2500x2500 |

8.3 |

5.35 |

| 120 |

11500x2500x2700 |

9.65 |

8.6 |

| 150 |

12000x3000x2700 |

11.22 |

8.6 |

| 170 |

16000x2500x2700 (Two groups) |

12.26 |

8.6 |

| 200 |

20000x2500x2500 (Two groups) |

15.53 |

9.3 |

| 250 |

24000x2500x2700 (Two groups) |

17.3 |

12.8 |

| 300 |

24000x 3000x2700 (Two groups) |

20.05 |

12.8 |

| LOGO customization |

Supportable |

| Outer packaging customization |

Supportable |

Appearance customization |

Supportable |

According to water sources, water quality, flow rate and ground area to design |

FAQ

What type of sewage is not suitable for this equipment?

It is not designed for high-toxicity sewage (e.g., heavy metal-containing wastewater) or high-oil sewage (e.g., restaurant grease traps without pre-treatment). For such cases, a pre-treatment unit is required .

How to replace the filter media?

The equipment has a detachable top cover. To replace the filler, simply open the cover, remove the old media, and add new media—taking 1-2 hours with basic tools .

What is the water pressure requirement?

The inlet water pressure needs to be 0.2-0.4MPa. If the water pressure is too low, an optional booster pump can be installed .

Does it produce sludge?

Yes, but the sludge volume is small (about 0.5L/d for a 5m³/d system). The sludge is collected in a small tank at the bottom of the equipment and can be disposed of with domestic garbage (after dewatering) .