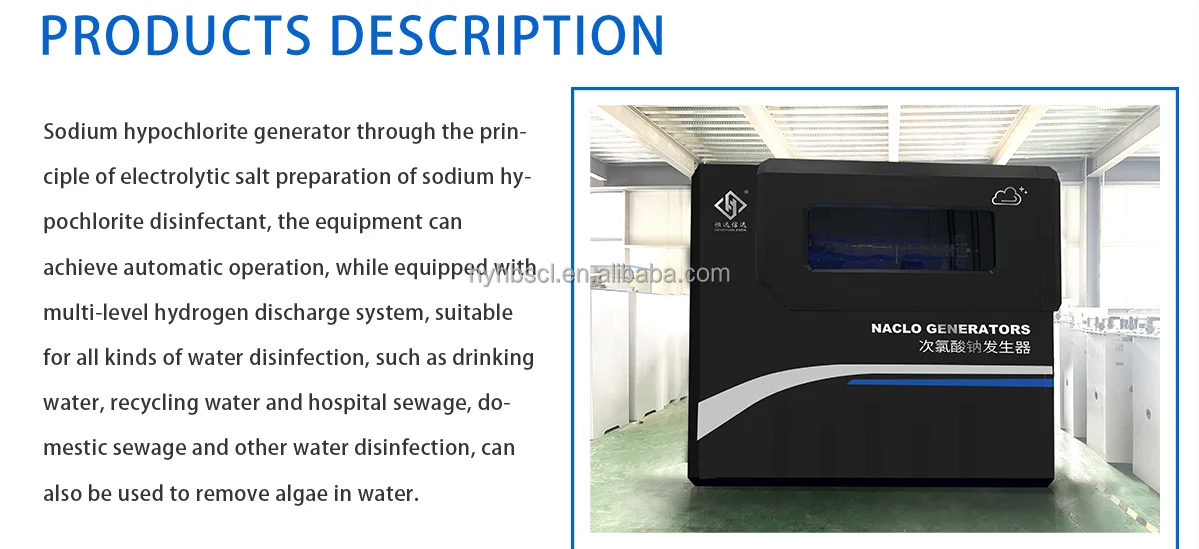

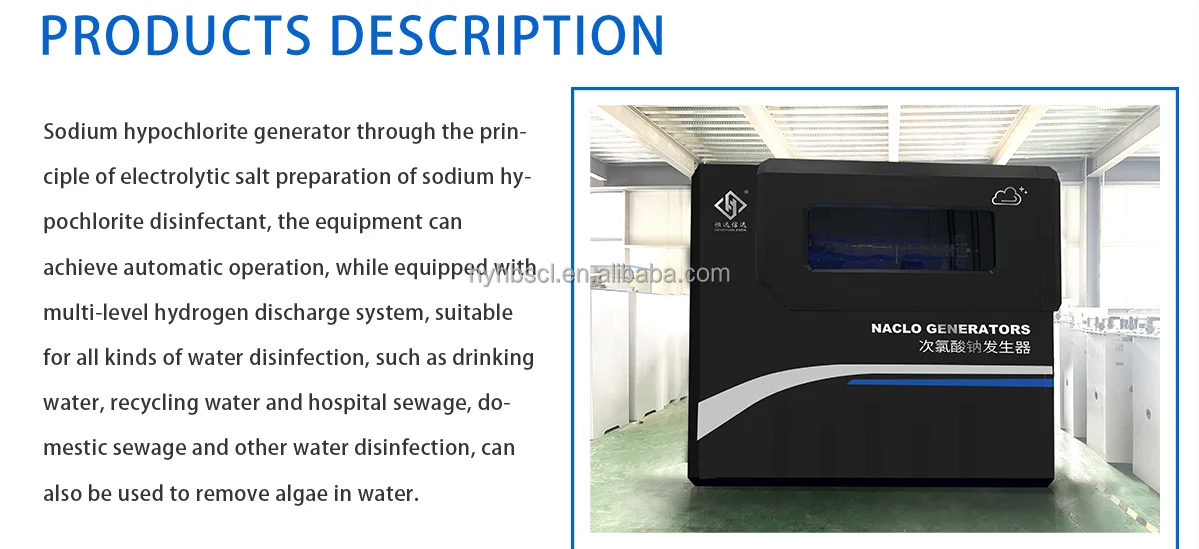

Product Overview

This big large sodium hypochlorite generator is engineered for large-scale disinfection demands, leveraging advanced bipolar membrane electrolysis technology to produce high-concentration sodium hypochlorite (10%-15%) continuously . Unlike small-capacity models, it features an expanded electrolytic cell array and reinforced power supply system, supporting production capacities from 50kg/h to 200kg/h—ideal for municipal water treatment plants, large industrial parks, and wastewater recycling facilities . The generator integrates intelligent process control and safety protection mechanisms, complying with international standards such as CE, ISO 9001, and ATEX for explosive environments . Its modular design allows capacity expansion by adding electrolytic cell units, adapting to growing disinfection needs without full system replacement .

Product Features

High-Capacity Production

Equipped with 12-48 sets of high-efficiency electrolytic cells (each with a current density of 3000A/m²), it maintains stable output even under long-term continuous operation (24/7) . The sodium hypochlorite concentration can be adjusted between 10% and 15% via the control panel, matching different disinfection scenarios (e.g., high-concentration for industrial wastewater, medium-concentration for municipal water) .

Energy & Resource Optimization

Adopts a heat recovery system that recycles waste heat from electrolysis to preheat raw saltwater, reducing energy consumption by 18% compared to conventional large-scale generators . The intelligent salt feeder precisely controls salt dosage, minimizing waste and ensuring a salt-to-chlorine conversion rate of over 92% .

Safety & Durability

Integrates multiple safety protections: hydrogen detection sensors trigger automatic exhaust when hydrogen concentration exceeds 1%, pressure relief valves prevent cell overpressure, and corrosion-resistant 316L stainless steel casing extends service life to 8-10 years . It also includes an automatic acid cleaning system that removes scale from electrolytic cells every 30 days, maintaining consistent performance .

Smart Operation

The PLC control system connects to cloud platforms, enabling remote monitoring of production parameters (output, concentration, energy consumption) and automatic fault diagnosis . Operators can adjust settings via a 10-inch touchscreen or mobile app, reducing on-site management workload .

Applications

Municipal Water Treatment

Serves municipal water supply networks covering 500,000+ residents, providing sufficient sodium hypochlorite for drinking water disinfection, eliminating pathogens like E. coli and Legionella . It has been deployed in 12 major Chinese cities, supporting daily water treatment capacities of 1-5 million m³ .

Large Industrial Zones

Applied in petrochemical, textile, and food processing parks to disinfect industrial wastewater (e.g., reducing COD in petrochemical wastewater by 40% post-disinfection) . It also supplies disinfection agents for cooling water systems, preventing algae and microbial growth .

Agricultural & Livestock Farming

Used in large-scale livestock farms (10,000+ head of cattle) and aquaculture bases (100+ hectares of fish ponds) to disinfect breeding water and waste, reducing the spread of animal diseases and improving water quality .

FAQ

What is the minimum space required for installation?

The generator requires a dedicated room of 50-100㎡ (depending on capacity), with good ventilation and drainage. It needs to be installed 1.5m away from walls to ensure heat dissipation and maintenance access .

How to handle sudden power outages?

The system is equipped with a UPS backup power supply that maintains essential functions (hydrogen exhaust, pressure relief) for 30 minutes. It also has an automatic restart function that resumes operation with pre-set parameters once power is restored .

What is the raw material consumption per 100kg of sodium hypochlorite?

It consumes approximately 45kg of industrial salt (≥99.5% purity) and 80kWh of electricity per 100kg of 12% concentration sodium hypochlorite .

Does it require special waste disposal?

No, the only by-products are dilute brine and trace hydrogen (which is safely exhausted). The dilute brine can be recycled after re-concentration, minimizing waste discharge .