Product Overview

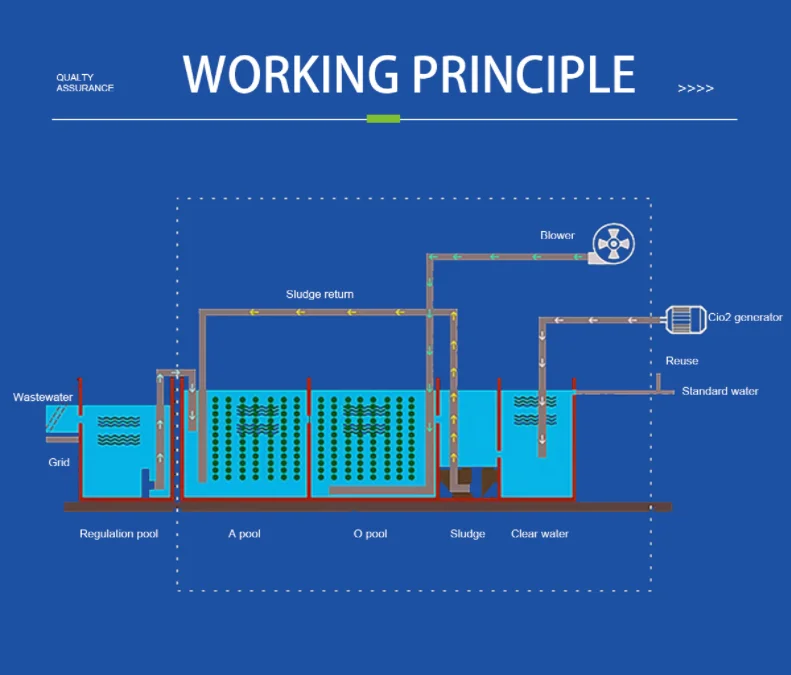

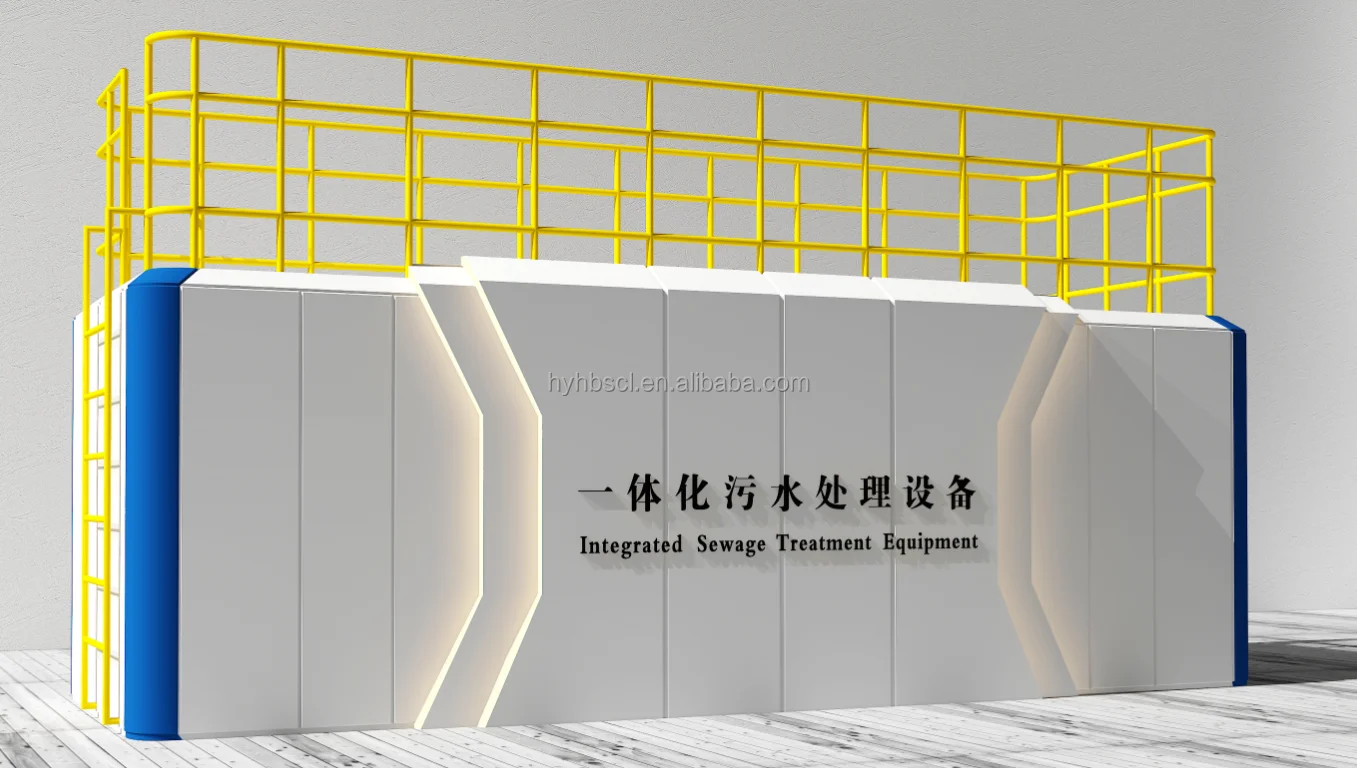

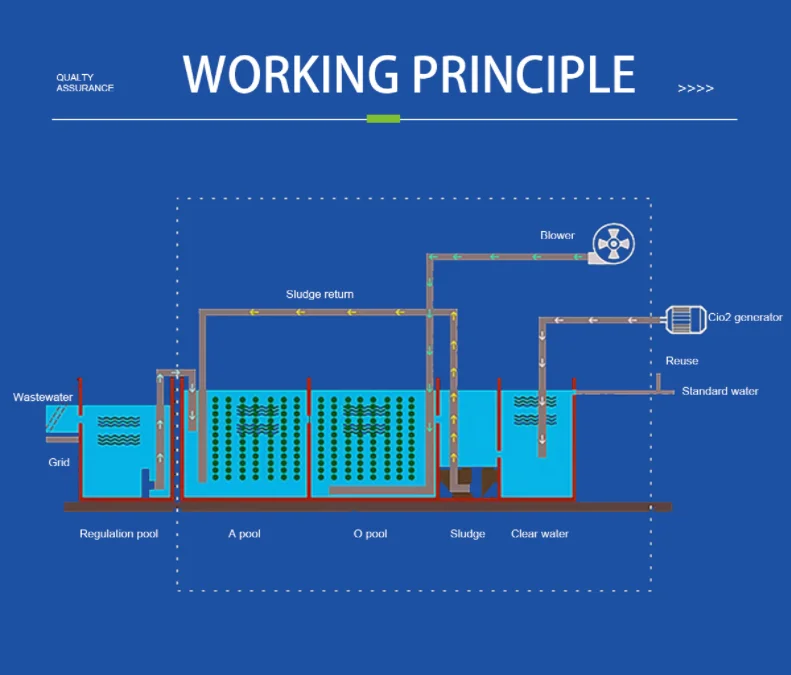

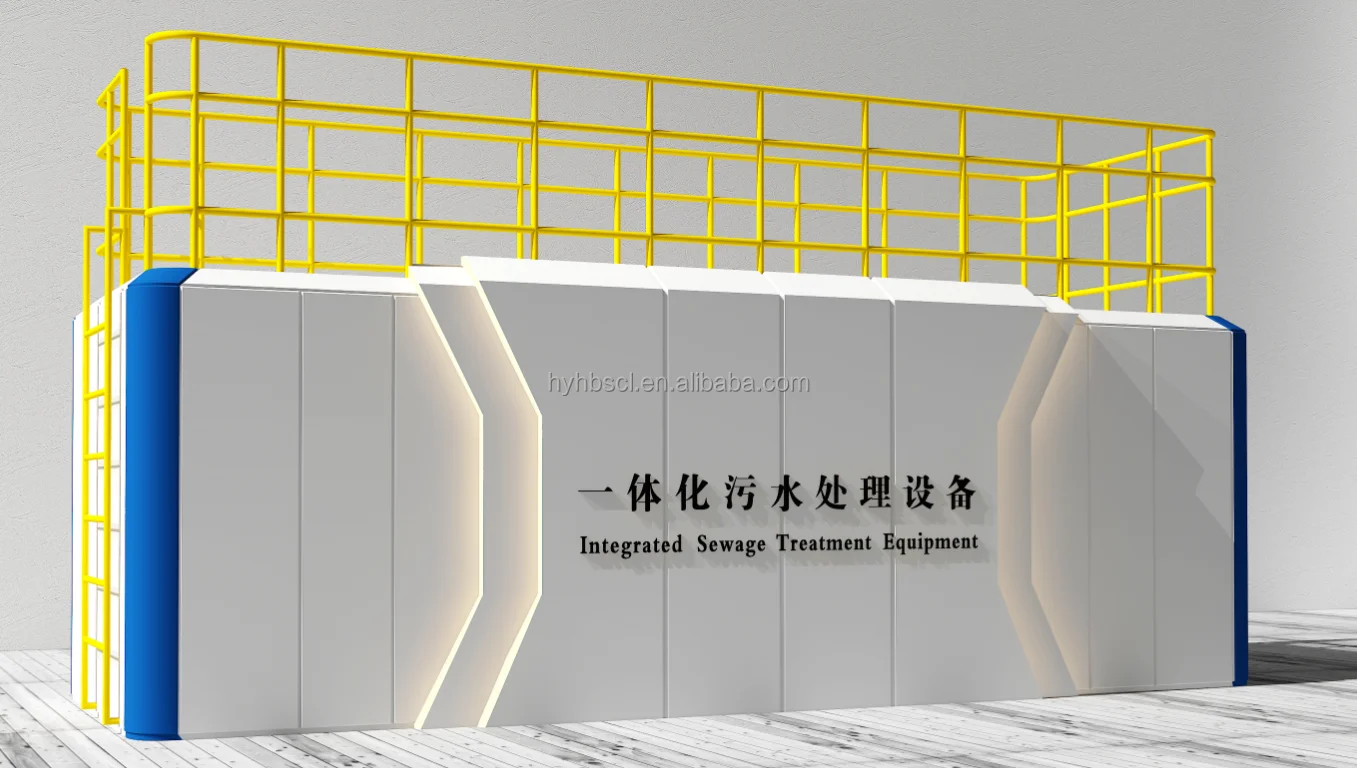

This auto-integrated mini wastewater treatment plant is a decentralized, high-efficiency system combining multiple purification technologies for small-scale sewage treatment . Designed as a fully automated unit, it integrates pretreatment, biological reaction, sedimentation, and disinfection into a compact module, requiring minimal manual operation . With a focus on energy efficiency and adaptability, it handles various wastewater types (domestic, light industrial) and delivers effluent meeting national discharge or reuse standards . The system’s containerized design supports rapid deployment and customization based on site conditions .

Product Features

High Treatment Efficiency

Utilizes a hybrid process (suspended growth + biological membrane) to achieve BOD removal rates over 90% and TSS removal over 95% . It effectively decomposes organic pollutants and reduces ammonia nitrogen levels to ≤15mg/L.

Fully Automated Operation

PLC control system enables automatic level monitoring, pump activation, and chemical dosing . Remote monitoring functionality allows operators to track performance and troubleshoot via mobile devices.

Adaptable Design

Containerized units are insulated and weather-resistant, suitable for extreme temperatures (-10°C to 45°C) . Multiple sizes are available, with processing capacities ranging from 1m³/h to 50m³/h to match community or factory needs.

Space & Cost Efficiency

The compact structure reduces footprint by 40% compared to traditional sewage plants . Low energy consumption (3-8kW/h) and minimal sludge production lower long-term operational costs.

Applications

Rural & Suburban Areas

Serves villages and small towns with 50-500 households, replacing outdated septic systems to improve water quality .

Small Industrial Parks

Treats wastewater from light industry (food processing, garment manufacturing) before discharge or on-site reuse .

Temporary Settlements

Deployed in construction camps, disaster relief zones, and military bases for rapid sewage treatment .

Tourist Resorts

Handles sewage from hotels and resorts in ecologically sensitive areas, ensuring compliance with strict environmental regulations.

FAQ

How long does installation take?

Containerized models require 3-5 days for on-site placement and pipe connection; non-containerized systems take 2-3 weeks .

What maintenance is required?

Monthly tasks include filter replacement and sediment discharge. Annual overhauls involve checking pumps and cleaning biological reactors.

Can it handle industrial wastewater with high COD?

Yes, the enhanced biological module can treat wastewater with COD up to 1000mg/L. For higher concentrations, a pretreatment unit can be added .

Does it have noise reduction features?

Yes, the system is equipped with sound-insulated enclosures, keeping operating noise below 60dB, suitable for residential areas .

Product Details

Water treatment capacity(m3/d) |

External dimensions: length*width*height(mm) |

Equipment weight(t) |

Operating power (kw) |

| 5 |

2500x1000x 1500 |

0.97 |

2.72 |

| 10 |

2500x 1500x 2000 |

1.65 |

2.72 |

| 20 |

5000x1500x 2000 |

2.5 |

3.1 |

| 30 |

5000x2000x 2000 |

2.9 |

3.85 |

| 40 |

6500x 2000x2000 |

4. 36 |

3.85 |

| 50 |

6500x 2000x2500 |

5.07 |

3.85 |

| 60 |

7500x2000x2500 |

5.58 |

4.55 |

| 70 |

7000x 2500x 2500 |

6.31 |

4.55 |

| 80 |

8000x 2500x2500 |

6.88 |

5.35 |

| 100 |

10000x 2500x2500 |

8.3 |

5.35 |

| 120 |

11500x2500x2700 |

9.65 |

8.6 |

| 150 |

12000x3000x2700 |

11.22 |

8.6 |

| 170 |

16000x2500x2700 (Two groups) |

12.26 |

8.6 |

| 200 |

20000x2500x2500 (Two groups) |

15.53 |

9.3 |

| 250 |

24000x2500x2700 (Two groups) |

17.3 |

12.8 |

| 300 |

24000x 3000x2700 (Two groups) |

20.05 |

12.8 |

| LOGO customization |

Supportable |

| Outer packaging customization |

Supportable |

Appearance customization |

Supportable |

According to water sources, water quality, flow rate and ground area to design |