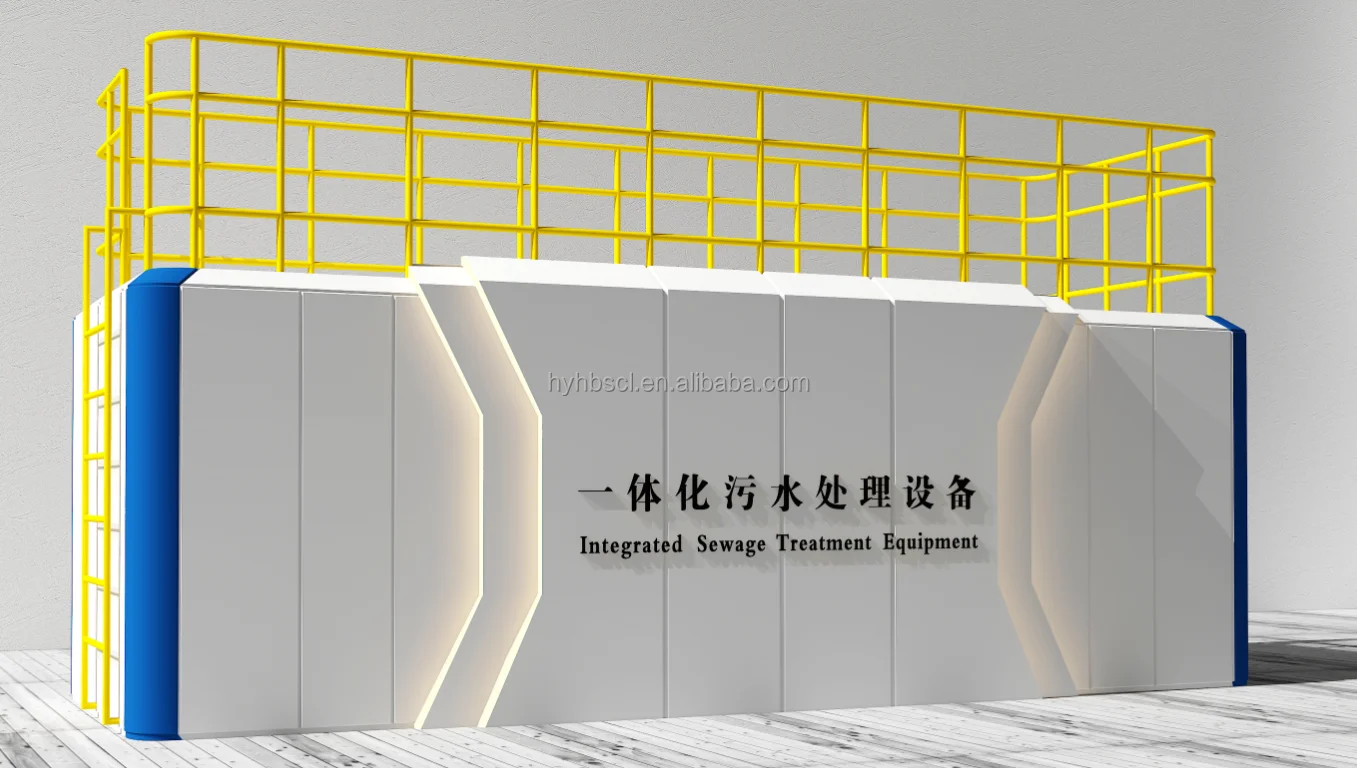

Product Overview

This integrated mini containerized sewage treatment plant packages all sewage treatment processes—pretreatment, biological reaction, sedimentation, disinfection, and sludge storage—into a standard 20ft or 40ft shipping container . Designed for rapid deployment and decentralized use, it eliminates the need for on-site civil engineering, reducing installation time to 1-2 days . The system handles sewage volumes from 5m³/d to 50m³/d, with effluent meeting Grade B discharge standards (GB 18918-2002) or reuse standards for irrigation . Its compact design and weather-resistant container casing make it suitable for remote areas, construction camps, and small rural communities .

Product Features

All-in-One Container Design

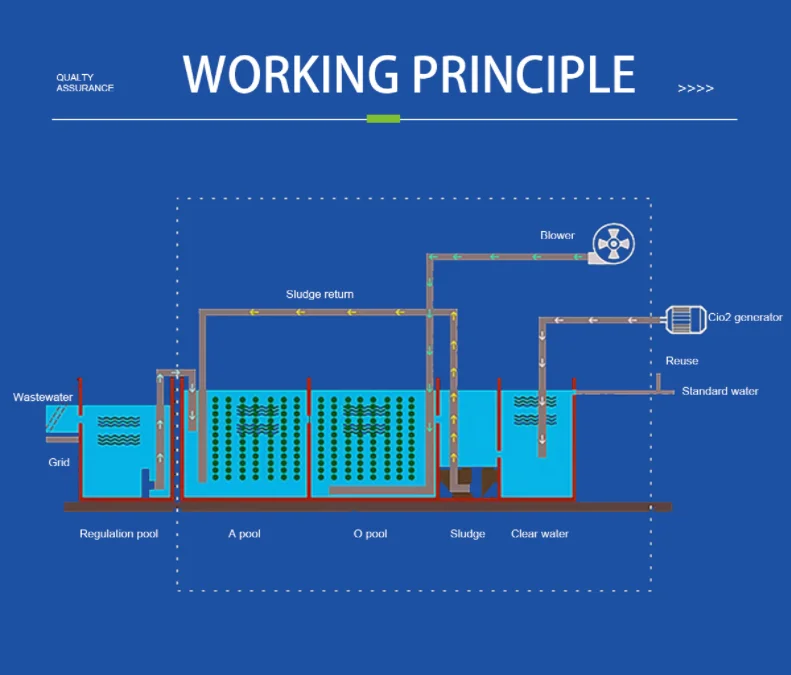

The 20ft container (L6058×W2438×H2591mm) houses all components: a grit chamber (pretreatment), a sequencing batch reactor (SBR, biological treatment), a small lamella clarifier, an ultraviolet (UV) disinfection unit, and a sludge tank . The 40ft model expands capacity with additional SBR tanks and a larger sludge storage area .

Easy Transportation & Installation

The container is equipped with lifting lugs and forklift pockets, enabling transportation via truck, ship, or train. On-site installation only requires connecting inlet/outlet pipes and power (AC 380V/50Hz), with no need for concrete foundations .

Low Operation & Maintenance

The SBR system operates in cyclic mode (fill-react-settle-draw), reducing aeration energy consumption by 25% compared to continuous-flow systems . Routine maintenance only involves weekly grit chamber cleaning and monthly UV lamp inspection—no professional operators required for daily use .

Environmental Adaptability

The container’s walls are insulated with 50mm thick rock wool, and the internal components are corrosion-resistant (304 stainless steel or FRP). It can operate in temperatures from -15°C to 45°C, with an optional heating system for cold regions .

Applications

Remote Rural Communities

Serves villages with 50-500 residents, replacing traditional septic tanks that cause groundwater pollution. The treated water can be used to irrigate farmland, improving crop yield .

Construction Camps & Mining Sites

Deployed in temporary construction camps (50-200 workers) and mining areas, providing on-site sewage treatment to avoid environmental fines. It can be moved with the camp as the project progresses .

Tourist Scenic Spots

Installed in small scenic areas or campgrounds, treating sewage from hotels and public facilities. The compact design minimizes impact on the natural landscape .

FAQ

How long does it take to start the plant after installation?

After pipe and power connection, the SBR tank needs 7-10 days of microbial acclimation (using activated sludge inoculation). Once acclimated, the plant can operate at full capacity .

What is the power consumption?

The 20ft model consumes 2-3kW/h (mainly from aeration blowers and pumps), while the 40ft model consumes 4-6kW/h—equivalent to the electricity usage of 2-4 households .

Can the container be customized?

Yes, the container can be modified to include a rainwater collection system, a solar power accessory (for off-grid areas), or an effluent recycling pump for on-site reuse .

How often is sludge removed?

The sludge tank has a storage capacity of 1-3m³. For a 20ft plant treating 20m³/d sewage, sludge needs to be removed every 2-3 months using a vacuum truck .